| g e n u i n e i d e a s | ||||||

|

|

|

|

|

|

|

| home | art and science |

writings | biography | food | inventions | search |

| something's cooking |

|

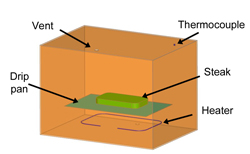

Dec 2012 Our five senses are truly astonishing. We can smell an individual odor molecule hidden among trillions of gas atoms. We can hear sound murmuring against our ear drum, as it vibrates by less than the diameter of an atomic orbital in response. And we can watch a single photon of light flash within our retina. But we can't see heat. Or peer inside a steel oven with x-ray vision. Which is too bad, as so much cooking involves precise temperature control, both in and around our food. Now, a great digital thermometer might help (as would an IR camera, if you have $10k to throw around). But if our goal isn't to monitor cooking in real time, but simply to devise optimal recipes and techniques, computer simulation is ideal. No burnt experiments. No drippings to cleanup at the end of the day. So I've begun a series of computer simulations analyzing what happens inside the impenetrable oven. This first article offers a brief peek inside a kitchen oven cooking a large prime rib. Later experiments will examine steaks and birds of varied sizes, cooked at multiple temperatures, both in the oven and on the grill. But for now, prime rib is on the menu to help my colleague Meathead illustrate his recipe posted at AmazingRibs.com These computational flow dynamic simulations were generated in a customized Autodesk software environment1. They are qualitatively accurate, but quantitatively imprecise due to a range of unavoidable approximations. Never the less, the model closely mimics a standard electric kitchen oven. A 3kW electric heater bar is mounted on the bottom of an insulated steel box. A simple thermostat controls the oven cycle (note the thermostat is located near the rear upper right corner of the oven). The wall insulation is only modestly effective, e.g. if you turn off the oven it drops in temperature by half in 45 minutes. While air leaks out of the oven through the door gasket and vents at a rate equal to about 5 full oven volumes an hour. Your standard kitchen appliance. When you open the door of a pre-heated oven to insert a hunk of meat, the air temp temp immediately drops, and the thermostat kicks on. But the heater bar isn't the only thermal source inside the oven. The walls, and surprisingly, the meat itself dramatically effects how quickly and uniformly the oven cooks. This first simulation follows a steak as it cooks in a 400F oven for around five minutes. Notice how the meat acts like a block of ice. Cold air, being denser than hot, cascades off the 35F steak, and slides along the drip pan (located just 2" below). Meanwhile, hot air is rising from the electrodes, bouncing off the drip pan, and then languorously circulating up and around the roast. An oven is a dynamic environment, with passing weather fronts and periods of drought.

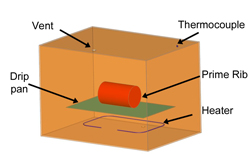

The meat is surrounded by its own microclimate- a bubble of cooler air and local humidity- that is as significant to the end result as is the heat generated by the oven2. Now onto the prime rib- an ample piece of meat (5 lbs, 4" round and 8" long) cooked low and slow. Unlike the steak, which forms a cold cave above the drip pan, the more rounded shape of a roast does not trap cold air as efficiently. But, as can be seen in this movie documenting the first 30 minutes of a 2:20 long cook at 225F, it's still colder near the surface.

Because the roast is so thick, the recipe calls for a 225F oven so the interior has time to catch up with the exterior. There is a substantial gradient across the meat, but it would be even greater if cooked at higher temperatures3. The surface would dry out while the interior remained raw. This gradient occurs because heat penetrates into a substance at a fixed rate, depending on its thermal conductivity and heat capacity. Its a bit like exiting a stadium after the big game. You can walk down the stairs only so fast. If the crowd is large, people start jamming up on the stairwell entrances, and there are more people at the top than the bottom. If the crowd is sparse (e.g. low temperature), the stairwell is evenly populated. Fortunately, despite these inevitable gradients, after cooking slow and low you let the meat "rest" at room temperature for 15-30 minutes. This resting helps the meat stiffen slightly, so its easier to cut. It encourages the juices to emerge on the plate instead of the cutting board (but does not effect how much juice is lost). And it lets the thermal gradient relax and even out, so the entire roast is more or less at the same temperature when serving. Even though the meat is sitting on your counter, the hot surface diffuses towards the center- hot meat heating cold. But without a new source of energy to keep the surface warm, the interior catches up with the exterior, until the entire roasts begins to cool off. These side views illustrate the resulting temperature profile INSIDE the roast (BLUE is 35F, GREEN is 115F and RED is 185F or above). The last few frames demonstrate how the temperature equilibrates during resting, though an observant viewer will notice the end caps are always warmer because they are heated from all sides (the same reason the corner of lasagna tray is crisper).

Check back soon for more simulations, which we plan on using to develop an accurate cooking time guide. Just too bad we can't eat our software experiments.

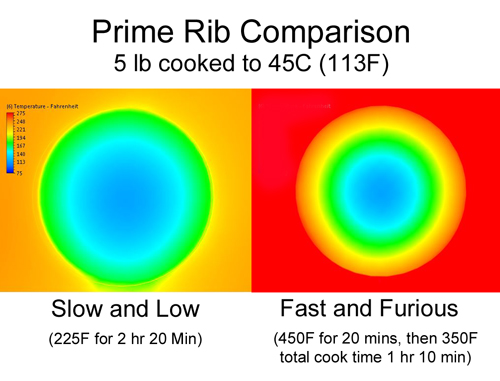

|

|

-------------------------------------------------------------------------------------------------------- 1 While Autodesk software implements standard Navier-Stokes, Fickes Law and black body equations (among others), it cannot handle evaporation of moisture from within the roast, which would cool off the meat's surface in a way not reflected by these simulations. This effect is larger at medium temperatures where the surface cooling effect is comparable to the energy absorbed from hot oven air, so it tends to extend cooking time. Working on obtaining a more sophisticated flow simulator as well as extending a heuristic model in Autodesk- until then, the effect of humidity will have to wait. So these curves are qualitative guides, not quantitative. 2 This microclimate is even more important when cooking quickly or during baking- more on how to tweak your cookie recipes in this article. 3 Some recipes recommend cooking prime rib in a very hot oven to initially build up a crust, and then drop the oven temperature to more gently heat the interior. I simulated one such recipe and compared it to slow and low. These images are taken just before resting the meat (or in the case of slow and low, before a quick sear and then resting), to highlight the much larger temperature gradient produced by the "Fast and Furious" approach. But remember, if you sear the "Slow and Low" roast for more than a few minutes over a high flame, you can easily destroy the uniform interior so carefully built up over 2-3 hours.

In this image, BLUE is the target temperature of 115F. RED is 275F or above.

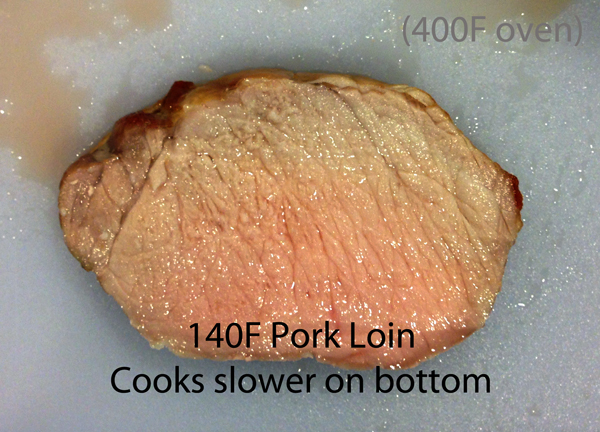

For comparison, this data taken on actual pork roasts illustrates how the interior and exterior temperatures can diverge by more than 50F. The surface easily exceeds 200F, while the interior is still medium rare. Most of the meat is overcooked. (1 kg, 2.2 lb 6"x4"x3") pork loin roasts in a 400F oven. You may also have noticed in the simulation that the meat on the bottom cooks slower than the top, due to the effect of the drip pan creating a colder micro-climate. You can clearly see this effect in a real pork roast placed a half inch (instead of an inch) above the pan. Note how it is pinker along the bottom than the top, especially given the flat profile of the roast bottom which excludes hotter oven air. A compelling reason to flip the roast, when cooking fast and furious.

|

Contact Greg Blonder by email here - Modified Genuine Ideas, LLC. |