| g e n u i n e i d e a s | ||||||

|

|

|

|

|

|

|

| home | art and science |

writings | biography | food | inventions | search |

| nailing it |

|

May 2013 A baked potato roasting over a bed of hot embers exudes a singularly earthy aroma. Triggering fleeting images of your first camping trip. Or prime rib in the holidays. For me, the skin is the best part. After gutting the potato I oil and salt the skin-- grilled, it's everything potato chips should be. For many years, restaurant potatoes were wrapped in foil and more or less steamed- an abomination in many people's mind. Though an understandable short cut- a large spud might take an hour to bake, too long to be cooked to order. So foil holds it moist and ready for service. Today, if you are in a hurry, a quick 15 minute pass through the microwave, followed by 10 minutes in a 450F oven, will do the trick. An alternative method is to roast the potato on a spit. More precisely, by impaling the potato with a 1/4" diameter, six-inch long nail. The theory being the metal nail conducts heat deep into the center of the potato, and in the words of one commercial, reduces cooking time by "up to 50%". But what are the trade-offs, and how much time can be saved? So lets compare three approaches to "baking" a potato": microwaving, nailing, and foiling, against simply cooking in a hot oven. Microwaving Microwaves are a form of light energy, but of a very long wavelength. While sunlight on a cold autumn day simply warms the surface of your skin, microwaves penetrate thousands of times deeper. In a potato, as deep as a few cms. So, instead of waiting for heat absorbed on the skin to slowly diffuse to the center, a microwave immediately dumps electromagnetic energy into a thick surface layer. In fact, if your food is thinner than the "penetration depth", it cooks through more or less uniformly (see this article on the science of microwave cooking). The penetration depth varies with temperature. In water (and potatoes are 70% moisture) around a half cm deep at room temperature, rising to 4 cm near 212F. So when you first "nuke" a potato, it only cooks the outer flesh. As heat diffuses inward, the penetration depth increases in parallel, and near the end of the cook, microwaves are cooking the entire spud simultaneously. In this experiment, I compared baking three Idaho potatoes in a 400F kitchen oven, to nuking three potatoes in casserole dish. Both ovens started out "cold", and to save a bit of time, I placed the potatoes in the electric oven while it pre-heated. "Doneness" was determined by inserting a fork until it penetrated smoothly to the center (around 208F for waxy potatoes like red bliss, 210F for russets like Idaho- depends a bit on cooking time).

(12 oz Idaho russet potatoes, temperature measured in center. Both ovens initially cold) As you can see, the microwaved potatoes took around 15 minutes to cook through, while the oven-baked potatoes, a bit more than an hour. To be fair to the electric oven, the microwaved potatoes are not quite ready for service. Microwaves bounce around inside the oven, and in some places the waves interfere with each other, reducing their intensity (think about the shadows and light spots on the bottom of a swimming refracted from the waves on the surface). Small marble-sized regions were slightly grainy and underdone. The potato needed to rest for 10 minutes or so for the temperature to equilibrate. Also, the more potatoes you cook, the longer they take in the microwave. The same graph above compares the cooking speed of three potatoes in the electric oven, to three in the microwave (e.g. a left or right, and middle spud). In an electric oven, there is no "loading" effect. The oven is powerful (around 5000 watts) and the poor thermal conductivity of air prevents one cold potato from slowing the cooking speed of its neighbor. But, in a microwave oven one potato can absorb incident radiation before it has a chance to reach its neighbor- for example, the middle potato bakes more slowly because it is shadowed by the left and right potatoes. Also, the microwave is underpowered by comparison (only 1000 watts) and the mere presence of more mass in the cooking chamber discourages microwaves from entering the oven from the power supply (again, discussed in this article on the science of microwave cooking). Finally, microwaved potatoes are a bit soggy, and if you like crispy skin, are best finished in an oven. So I also compared cooking a potato (in this case a red bliss) in an electric oven, to starting in a microwave while pre-heating and finishing in the oven:

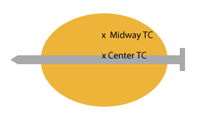

(12 oz waxy red bliss potatoes, pre-heated oven, temperature measured in center) A speed-up to be sure. In terms of flavor, the baked potato is my favorite (crispy skin, highly aromatic, tastes like a potato, and a nice blend of smooth and crumbly flesh), but the microwaved/baked was close behind. So this cooking method realistically speeds things up by a factor of 2 or so. If you have only 30 minutes to prepare dinner, it is the method of choice. But not much help camping or grilling. Which leads directly to impaling. Potato Nails We've all been mesmerized by ads for "potato nails" on late night TV. If grilling is a manly endeavor, impaling a potato over a hot fire verges on blood lust. Hard to resist the pitch, so I purchased a commercial spud nail kit. The spikes are manufactured out of food grade stainless steel1, and come four-to-a-set. To test, I baked a dozen 8 oz Idaho, Red Bliss and Yukon Gold potatoes in a 400F oven according to their instructions. If you can't speed up cooking at 8 oz, 12 oz is hopeless. Did it work as advertised? Well, if you think 10% counts as "up to 50%", it does speed up cooking. But hardly worth the effort. Here's why: Each potato was instrumented with two very small thermocouples. One was located in the center of the potato, the other, mid-way between the center and the surface. In the case of the nailed potato, the center thermocouple was not in the exact center of the spud, but immediately on the surface of the spike. An 8 oz red bliss potato is fully cooked at around 208F (as confirmed by poking with a narrow skewer). This is near 212F, where the potato cooking curve plateaus due to evaporative cooling, allowing both spuds to catch up with each other. But even throughout the cook, the center only ran about 5 minutes faster with the nail. Underwhelming.

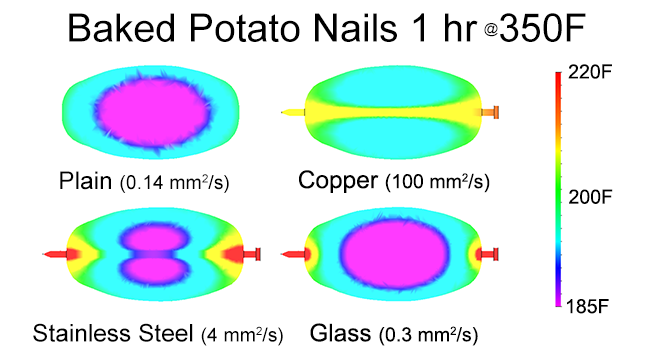

Still, the principle *appears* logical- why didn't it work as advertised? There are three reasons. First, the nail only heats a very small surface area inside the potato, compare to 10x greater surface outside the potato. Dramatically limiting its potential influence. Secondly, a potato is mostly water, and will begin to steam and evaporatively cool as it warms, ultimately holding its maximum temperature near 212F. Again reducing the effectiveness of impaling with a hot nail- much of the extra heat steams away before reaching the center. And third, and most importantly, a stainless steel nail isn't a very effective heat highway. Thermal diffusivity "D" characterizes how quickly heat travels down the nail into the cool potato. Glass, an excellent insulator, has a low D of 0.3 mm2/s. The potato is pretty poor as well, around 0.14 mm2/s. But stainless steel is only 4 mm2/s, compared to an excellent thermal conductor like copper (100 mm2/s)- around 25 times greater than stainless! This is why high-end sauté pans embed a thick copper disk beneath their stainless steel skins. The copper spreads the heat, preventing hot spots and charring. As you can infer from these images of a 12 oz potato cooked in a simulated oven, the nail's thermal diffusivity makes all the difference (purple is cold, red is hot). The stainless steel spiked potato is barely warmer than no spike at all.

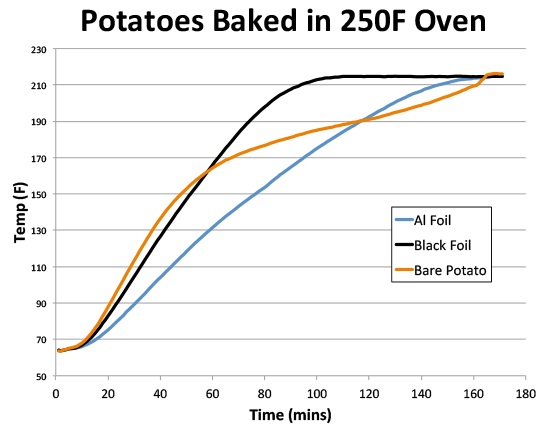

(12 oz potatoes vs a range of thermal diffusivities. The model includes the cooling effect of evaporation) A copper nail (or more safely, a copper nail within a stainless steel skin, or even coated with tin1, like in a tin can) might actually reduce cooking time in a small potato by half. But not plain stainless, or even plain steel. At home, if you are in a hurry, pre-cook with the microwave. Out camping? The whole point is to slow down and enjoy life. Use the nails to stake down your tent. Foiled Again As a Boy Scout, aluminum foil was our most trusted culinary friend. We'd hike to our camp site carrying a dozen packets of foil stuffed with frozen raw meat, sliced onions and veggies. Another dozen spuds nestled in foil. And a bag of marshmallows. Toss the foiled meal on the fire and it cooked unattended- the foil was a dutch oven and serving platter rolled up in one. Foil sealed in moisture, so the food steamed more than it roasted. And it sealed out insects and ash. But I always wondered if the shiny surface (like the mylar blankets in our emergency kit) might reflect so much heat, it was slowing down dinner. Why not black aluminum foil? It turns out black aluminum foil (which may or may not be food-grade) is available as anodized "black wrap" to cover theatrical spotlights and lamps. This foil is not painted, but rather dyed within the anodized surface layer. To test the effect of surface color, I baked three 12 oz Idaho potatoes in a 250F oven. One bare, one wrapped in shiny aluminum foil, and one in black foil. 250F is a slow oven, and more likely to dessicate than bake, but the results were telling:

The black potato cooked first, the aluminum-foiled second, and the bare potato in a close third. At this temperature, in this oven, about 70% of the energy arrives from the air as convective heat, and the rest as infra-red radiation. So the black foil was more efficient at absorbing this significant heat source. Note the bare potato curve starts to slow down at around 170F- evaporating moisture through the skin cools the surface. Foiled potatoes are sealed in their own private sauna, and only near boiling does built-up steam squirt out jets of cooling moist air though gaps in the foil. Which is why all three potatoes eventually plateau around 214F. The bare potato took three hours to cook, lost almost 20% of its initial weight, and was a bit dry. What about cooking at a more realistic oven temperature, like 400F?

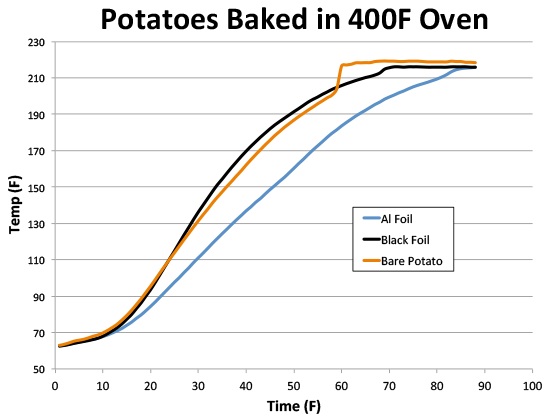

(12 oz potatoes. The jump at 60 minutes occurs when the potato cracks open due to shrinkage) The shiny aluminum foiled potato took the longest to cook. Not too surprising-- at this temperature IR heating contains almost 60% of the total oven energy. But why did the black-foiled and brown-skinned potato cook so similarly? Because evaporative cooling is less effective2 at higher temperatures, and because brown or black surfaces are both pretty good IR absorbers. So the surface of the potato almost immediately pins at 212F, and it is the surface temperature that cooks the interior, irrespective of the oven temperature. The aluminum foiled3 potato took longer for the surface to reach 212F. An aluminum foiled potato cooks SLOWER than a bare potato. It is definitely moister- losing only 5% (vs 10%) of its initial weight. And harder to overcook. However, the flavor is much closer to mashed than baked, and the skin is soggy. The higher moisture content and steamy environment inside the foil strongly gelatinizes potato starch. This gummy layer efficiently absorbs raw potato aroma, and with its absence, the flesh smells and tastes like mashed. If you grew up eating foiled baked potatoes, mashed is the taste you crave. Which is fine. I prefer the earthier flavor and crispy skin of naked baked potatoes. But this is a matter of choice.

|

|

--------------------------------------------------------------------------------------------------------

1 If you plan on roasting a meal over an open fire with a rotisserie, you might look for a spit made from a low conductivity metal. Otherwise, in a long cook the 1/2" thick spit can easily over-cook the food's interior, especially where it first penetrates. Stainless steel isn't a bad choice, but even better is a hollow rod- air is a 700x worse conductor than stainless. Grill spits (or potato nails) will contaminate and stain food if made from the incorrect material. For example, brass contains copper, zinc and lead- all potentially toxic except in trace quantities. As does a galvanized nail from the home center. Aluminum may not be able to stand the direct heat of the fire, and may corrode if the food or marinade is acidic. So food-safe stainless or chrome-plated steel are best- both are coated with a neutral layer of chrome oxide, which separates the food from the metal. Enameled steel is an alternative. 2 Evaporative cooling is powerful, but eventually fails to keep pace with rapid enough heat input. For example, I measured the equilibrium cooling (e.g. "stall") temperature of an open bowl of water in a kitchen oven. Note as the oven temperature increases, gentle evaporation has a harder time keeping up. Only at a full boil is enough moisture released to match heat input. Still, it is amazing that a bowl of water will not boil in a 400F oven!

(500 gms water, 60 cm2 exposed surface area, convection oven. At 400F the water is dissipating almost 13,000 watts/m2.) 3 The aluminum foiled potato also traps a bit of insulating air between the foil and the skin, which slows down heating. However, the bare potato skin also dries out and somewhat insulates and seals in moisture. So the difference is not as stark as one might imagine. |

Contact Greg Blonder by email here - Modified Genuine Ideas, LLC. |